In the rapidly evolving domain of material science, researchers at the Massachusetts Institute of Technology (MIT) have made a compelling breakthrough with their “strong but stretchy” metamaterial. At a cursory glance, terms like “flexibility” and “stretchability” might conjure images of software adaptability or the latest bendable screens. However, this new material pushes the boundaries of traditional definitions of flexibility to an extraordinary level: it can reportedly extend over three times its original size.

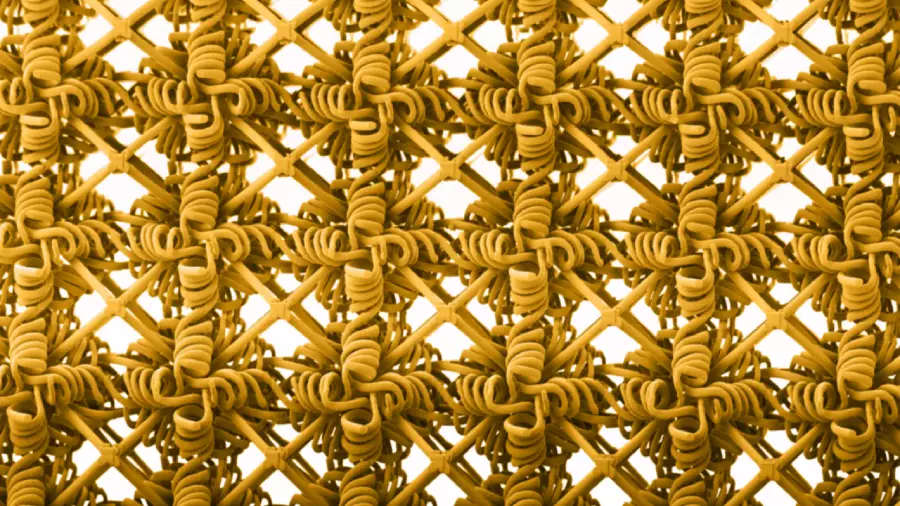

Metamaterials, substances engineered at a microscopic level, are designed to exhibit unique properties that exceed those of natural materials. The innovative metamaterial introduced by MIT comprises an intricate structure of a rigid grid overlaid with a network of coils. This dual-structure design employs the same acrylic plastic, which is meticulously fabricated using a high precision laser technique known as two-photon lithography. This novel combination not only provides a solid framework but also incorporates elasticity, allowing for unprecedented mechanical performance.

The Mechanics Behind the Magic

At the core of this innovation lies a fascinating interplay between structural integrity and flexibility. Professor Carlos Portela of MIT illustrates the design with a vivid analogy: envision a tangled mess of spaghetti encircling a sturdy lattice. When the rigid parts of the structure encounter stress, the tangled fibers respond in harmony, enhancing the entanglement and friction, which leads to superior energy dissipation.

The experimental setup used by the MIT team involved a specialized nanomechanical press to measure how the material responded under tension. Remarkably, the double-network design enabled the metamaterial to be stretched to three times its length without compromising its structural fidelity. This resilience bodes exceptionally well for a variety of future applications, as it demonstrates a balance of strength and flexibility that could redefine product engineering.

Unlocking Practical Applications Across Industries

The implications of this metamaterial extend far beyond academia and theoretical applications; the potential for real-world usage is formidable. MIT suggests this stretchable material could service a range of functionalities, including the manufacture of stretchy ceramics, glass, and metals that can withstand significant deformation. Imagine wearables made from tear-resistant textiles, implantable medical scaffolds that could adapt to the body, or even advanced flexible semiconductor technology.

The beauty of this metamaterial lies in its versatility—applications range from developing durable electronic devices to creating more reliable components within existing technology. Portable electronics, including laptops and tablets, often face physical stresses that lead to failures over time. The integration of a flexibly engineered motherboard with conducting traces that can bend without breakage paints a vivid picture of future devices that defy current limitations.

A Visionary Leap Toward Durable Devices

What truly sets this research apart is its potential to herald a new era of electronic and consumer device manufacturing. Consider the revolutionary implications for smartphones and tablets, which would no longer be at the mercy of drops or stress-induced fractures. As electronics evolve into increasingly integrated and compact forms, the metamaterial allows manufacturers to think outside traditional design constraints, embracing forms that were previously seen as risky or impractical.

Moreover, the notion of incorporating such materials into the foundation of computational architecture raises significant discourse on the future of tech design. Imagine circuits housed in materials that flex instead of fracturing, which could drastically alter how we approach durability in technology.

A Transformative Future Awaits

As researchers continue to explore the many facets of strong yet stretchy metamaterials, we are positioned at the cusp of transformative advancements in multiple sectors, from healthcare to consumer electronics. The ability to cross the threshold between strength and elasticity carries not only technological promise but also sparks imaginative possibilities that extend the horizons of material science. Future innovations leveraging this technology may lead us to redefine common assumptions, paving the way for a resilient, adaptable world where functionality and durability seamlessly intertwine. The exploration into these new materials signals an exciting frontier, challenging old paradigms and empowering industries to pursue the groundbreaking potential of elastic and robust designs.

Leave a Reply